How AI is Transforming the Manufacturing Industry

The emergence of AI, the field of computer science that aims to build intelligent machines, is transforming many industries, especially manufacturing. Manufacturers use AI technologies to enhance efficiency, decrease costs and design new production models. This blog explores the various aspects of AI in manufacturing and its applications, benefits, challenges, and future trends.

The Evolution of AI in Manufacturing

The inception of AI in manufacturing was for the simplest repetitive tasks. With machine learning and data analytics evolving, artificial intelligence began to handle more complex processes, a trend now manifesting itself in smart factories. These facilities leverage connected systems, Internet of Things (IoT) devices, and real-time data to optimise their operations, a significant departure from previous ways of doing things.

Artificial intelligence (AI) assists the intelligent production process by developing better decision-making capabilities and making smart factories that help in the smoother running of the process. They develop digital twins—virtual representations of real-world systems—to simulate and forecast performance ahead of physical manufacturing. This predictive ability minimises errors and enhances throughput, enabling manufacturers to fine-tune efforts before making expensive investments.

Key Applications of AI in Manufacturing

Predictive Maintenance

Predictive maintenance uses AI algorithms to check equipment health and predict failures. By analysing data from machine sensors, AI spots wear and tear patterns, allowing for timely repairs.

Traditional maintenance is either reactive or scheduled, which can be inefficient. AI-driven predictive maintenance ensures maintenance occurs when needed, cutting unplanned downtime and extending equipment life.

For example, BP uses AI to foresee issues in drilling operations and improve efficiency and safety. General Electric (GE) monitors jet engines and turbines with AI to prevent failures.

AI-Driven Quality Control

AI quality control systems use computer vision and machine learning to inspect products for defects. These systems quickly process images to identify and remove defective items from the production line.

In the past, human inspectors handled quality control but could fatigue and make errors. AI visual inspection systems are faster and more accurate, ensuring consistent product quality. BMW and Tesla use AI to spot tiny defects in car parts, cutting waste and enhancing reliability.

Supply Chain Optimization

AI improves supply chain management by predicting demand, optimising inventory, and spotting possible disruptions. Machine learning analyses sales data, market trends, and external factors to forecast demand accurately.

This helps manufacturers adjust production and inventory, lowering costs and boosting customer satisfaction. AI-powered platforms like IBM Watson Supply Chain and SAP’s logistics solutions enhance efficiency and resilience.

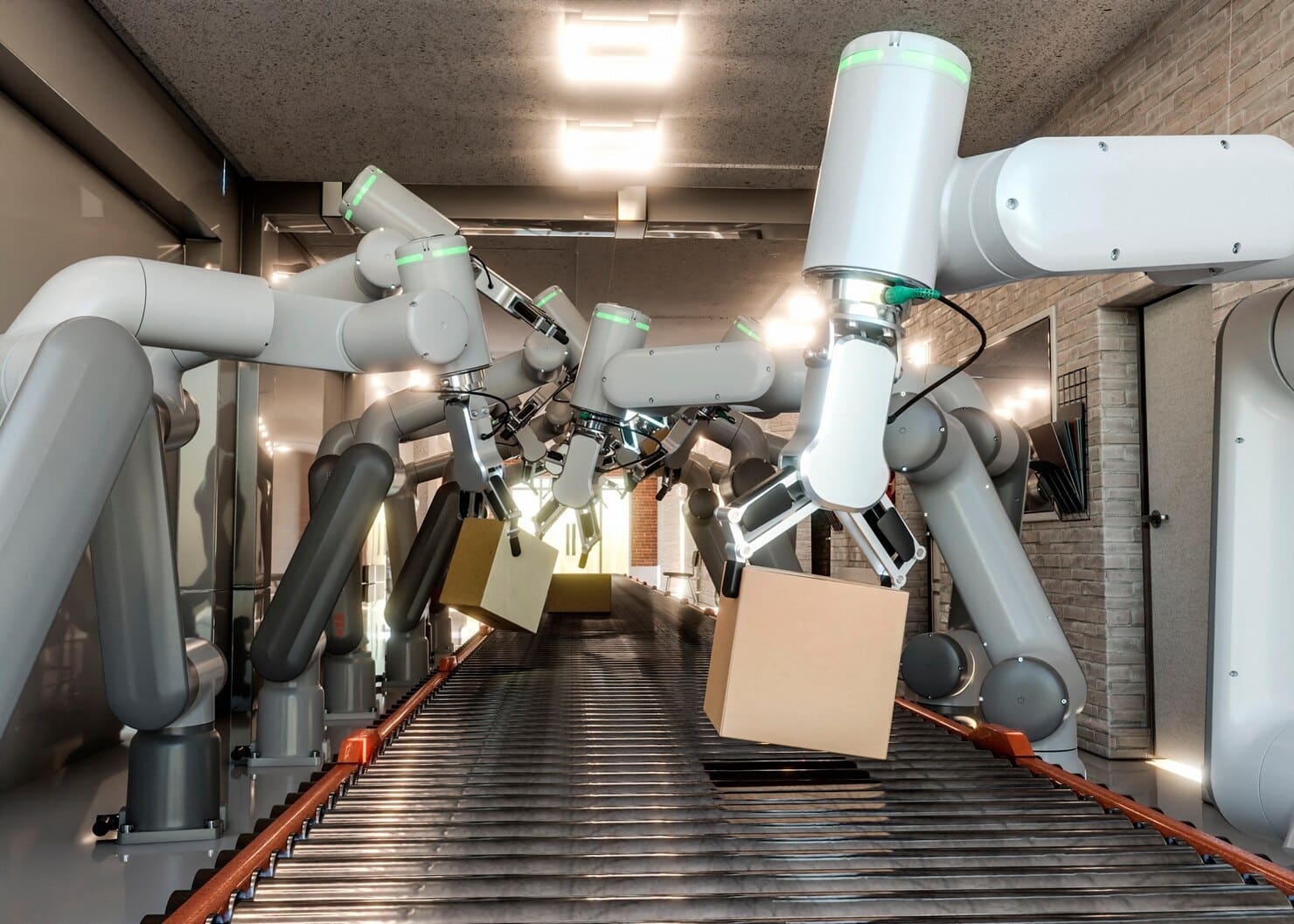

Robotics and Automation

AI and robotics integration has led to collaborative robots, or cobots, that work with human operators. These robots learn from human actions and adapt to new tasks, increasing flexibility in manufacturing.

Unlike traditional robots that need extensive programming, AI-powered cobots use reinforcement learning. For instance, Amazon employs over 750,000 mobile robots in its warehouses to boost efficiency and cut costs. Companies like Fanuc and ABB Robotics are at the forefront of AI-driven robotic systems.

Generative Design and AI-Driven Innovation

AI generative design software lets engineers input parameters and receive optimised design options. AI evaluates many possibilities, considering materials and performance needs. This speeds up the design process and often leads to innovative solutions.

Airbus and General Motors use generative design to create lightweight, strong components. Manufacturers can develop efficient and cost-effective products by leveraging AI’s data processing power.

Benefits of AI Integration in Manufacturing

- Increased Efficiency: AI automates tasks and optimises processes, speeding up production cycles.

- Cost Reduction: AI cuts downtime, reduces waste, and improves resource use, leading to savings.

- Enhanced Quality: Ongoing monitoring and real-time adjustments ensure consistent quality.

- Improved Safety: AI predicts hazards and automates dangerous tasks, safeguarding workers.

- Sustainability: AI optimises energy use and reduces waste, promoting eco-friendly manufacturing.

Challenges and Considerations

Despite the benefits, AI implementation in manufacturing has challenges:

- Data Security: Dependence on data requires strong cybersecurity to protect sensitive information.

- Workforce Displacement: Automation may displace jobs, especially for repetitive tasks. However, it opens new roles for managing AI systems. Countries like China see workers moving to technology management jobs.

- High Initial Investment: Implementing AI can be costly for small and medium-sized businesses.

- Technical Expertise: Developing and maintaining AI systems requires specialised skills, leading to training needs.

Case Studies: AI Transforming Manufacturing

Foxconn’s FoxBrain

Foxconn, a top electronics manufacturer, created FoxBrain to boost data analysis and code generation. Trained in four weeks, FoxBrain aims to optimise manufacturing and supply chain management.

Siemens’ Investment in AI

Siemens announced a $285 million investment in U.S. manufacturing, focusing on AI. This initiative aims to enhance capabilities and create over 900 skilled jobs.

AI in Sustainable Manufacturing

AI is key to promoting sustainable practices. Companies use AI-powered systems to manage energy, cut carbon footprints, and optimise resources. In viticulture, AI-driven tractors help with precision farming and lower fuel use.

The Future of AI in Manufacturing

The future of AI in manufacturing is about systems with greater autonomy. Developments may include:

Hyper-Personalization: AI will enable manufacturers to produce highly customised products in large quantities.

Sustainable Practices AI will optimise resource utilisation and energy usage for sustainable operations.

You can work with it and it with you.

Are you prepared to use AI to improve your production operations? Contact us today for the AI-based solutions you need!